Is Triple Glazing Worth it?

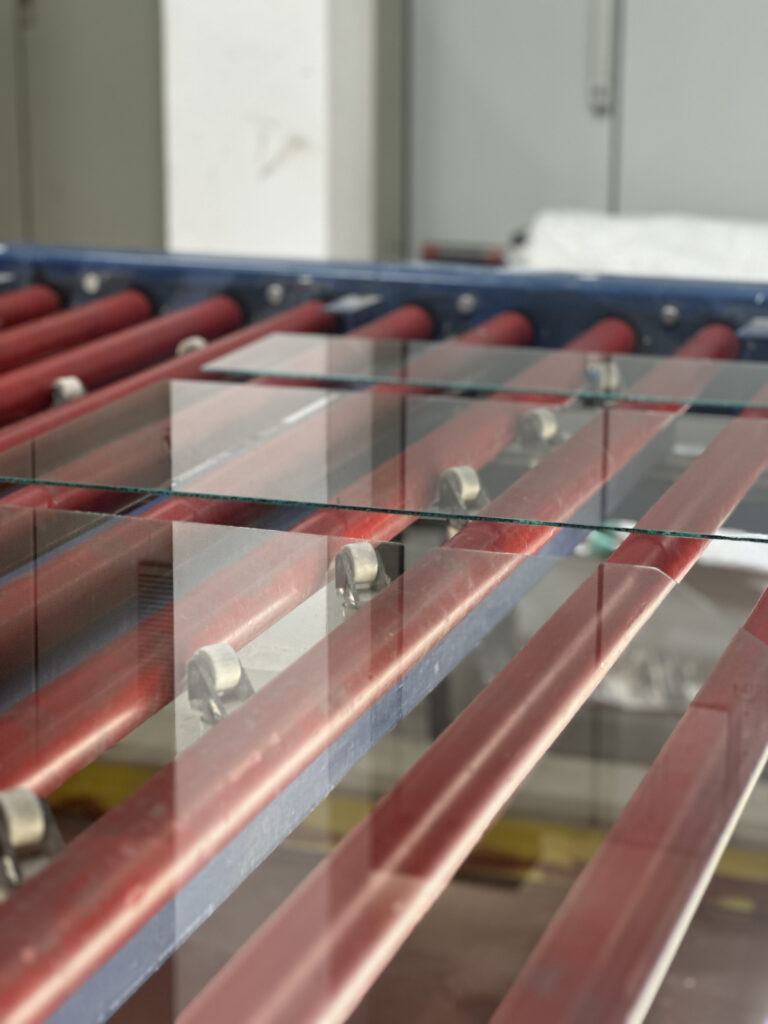

Is Triple Glazing Worth It? The quest for energy efficiency and comfort in our homes has led many to consider upgrading their windows. While double glazing has been the standard for years, triple glazing is gaining traction as a potential solution for enhanced insulation and noise reduction. But is it truly worth the additional cost and effort? This comprehensive guide delves into the pros and cons of triple glazing, helping you make an informed decision for your home. Understanding Triple Glazing Triple glazing technology utilises three panes of glass within one glazing unit, separated by two gaps filled with inert gas such as Argon. This configuration aims to boost thermal insulation and sound dampening properties beyond what traditional double glazing can offer. Definition and Explanation of Triple Glazing The third pane of glass in triple glazing acts as an additional barrier against cold air, ensuring that homes remain warmer during the winter and cooler in the summer. Beyond its thermal benefits, triple glazing is also highly effective in reducing noise pollution, making it an excellent choice for those living in busy or noisy areas. The increased durability and insulation provided by triple glazing make it a worthwhile investment for homeowners who prioritise quality and comfort. How Triple Glazing Works The principle behind triple glazing is straightforward – an extra layer of glass creates an additional barrier against heat transfer and sound waves. The spaces between panes are typically filled with argon or krypton gas. This setup effectively minimises heat loss and reduces external noise penetration. Comparing Triple Glazing to Double Glazing While double glazing uses two panes of glass with a single gas-filled gap, triple glazing adds another layer to the mix. This extra barrier can provide marginal improvements in energy efficiency and noise reduction. However, the extent of these benefits often depends on various factors, including the quality of installation and the specific needs of your home. When comparing double or triple glazing, it’s important to consider the benefits and drawbacks of each, such as cost and energy efficiency (u-value). Double glazing is generally more cost-effective, while triple glazing offers better energy efficiency but at a higher cost. The Benefits of Triple Glazing Triple glazing has several advantages that make it an attractive option for homeowners looking to upgrade their windows. Here’s just some. Enhanced Thermal Insulation One of the primary selling points of triple glazing is its superior thermal performance. Solar gain plays a crucial role in evaluating energy efficiency by determining how much heat from the sun can enter through the windows, significantly contributing to thermal performance. The additional pane and gas-filled cavity create a more formidable barrier against heat loss, potentially leading to lower energy bills and a more consistent indoor temperature. Improved Sound Insulation and Noise Reduction For those living in noisy areas, triple glazing can offer a noticeable reduction in external noise. The extra layer of glass and gas provides another obstacle for sound waves to penetrate, creating a quieter indoor environment. Increased Home Security The third pane of glass in triple glazing windows adds an extra layer of protection against break-ins. This can be particularly appealing for ground floor windows or homes in areas with higher crime rates. Potential for Reduced Condensation Triple glazed windows can help minimise condensation on the interior pane. The innermost pane remains closer to room temperature, reducing the likelihood of moisture condensing on its surface. The Drawbacks of Triple Glazing While triple glazing offers several benefits, it’s important to consider potential drawbacks before making a decision. Higher Initial Costs Perhaps the most significant barrier to widespread adoption of triple glazing is its cost. The triple glazed windows cost can be 10-20% more than double glazed windows, depending on the frame materials used. This can be a substantial investment for many homeowners. However, this investment does pay for itself over time with a reduction in energy costs. Cost of Triple Glazing The cost of triple glazing can vary widely based on several factors, including the type, size, style, and material of the window. On average, triple glazing costs about 20% more than double glazed windows. However, the exact price will depend on your home’s specific requirements and the installer you choose. It’s crucial to request quotes from multiple installers to compare prices and ensure you get the best value for your money. While the initial investment may be higher, the long-term savings on energy bills and the added comfort can make triple glazing a cost-effective choice. Factors that Affect the Cost of Triple Glazing Several factors can influence the cost of triple glazing, including: By considering these factors, you can better understand the potential costs and make a more informed decision about your investment in triple glazing. Making the Decision: Is Triple Glazing Right for You? Ultimately, the decision to invest in triple glazing depends on your specific circumstances and priorities. Assessing Your Home’s Needs Consider factors such as your local climate, current window performance, and overall home insulation when deciding if triple glazing is worth it for you. While new double glazed windows provide good efficiency and comfort, triple glazing offers superior performance, especially in colder climates, though it comes with a higher upfront cost. Balancing Cost and Performance Weigh the potential benefits against the higher initial cost, taking into account your budget and long-term plans for the property. New triple glazed windows can significantly reduce noise levels and enhance home comfort, making them a worthwhile investment. Seeking Professional Advice Consult with energy assessors and window specialists to get personalised recommendations based on your home’s unique characteristics. In conclusion, while triple glazing offers notable benefits in terms of insulation and comfort, its worth varies depending on individual circumstances. By carefully considering the factors outlined in this guide, you can make an informed decision about whether triple glazing is the right choice for your home. Remember, improving your home’s energy efficiency is a journey, and triple glazing is just one of many potential steps along the way. At

Is Triple Glazing Worth it? Read More »